CoolVisions comes to OR Winter Market

The only CO2 emitted is that absorbed by the plant during its growth.

13th April 2022

Innovation in Textiles

|

Kiyosu, Japan

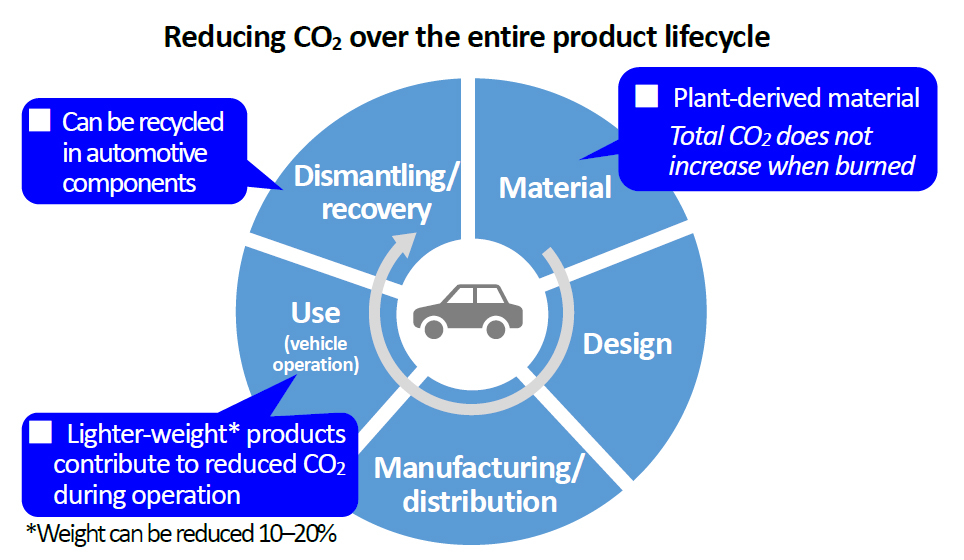

Tier 1 supplier Toyoda Gosei, headquartered in Kiyosu, Japan, has developed a cellulose nanofibre (CNF)-reinforced plastic which can reduce CO2 over the lifecycle of automotive components, from raw material procurement and production to recycling and disposal.

CNF has one-fifth of the weight and five times the strength of steel and when used as a reinforcing material in plastic or rubber, products can be made thinner and foam moulding becomes easier.

This reduces weight and contributes to lower CO2 emissions during driving.

When the material is reused after vehicles are scrapped, little strength is lost from heating and melting, making recycling in automotive components possible. It is also a material that does not increase the total amount of CO2. Even when CNF is incinerated, the only CO2 emitted is that which was absorbed by the plant during its growth.

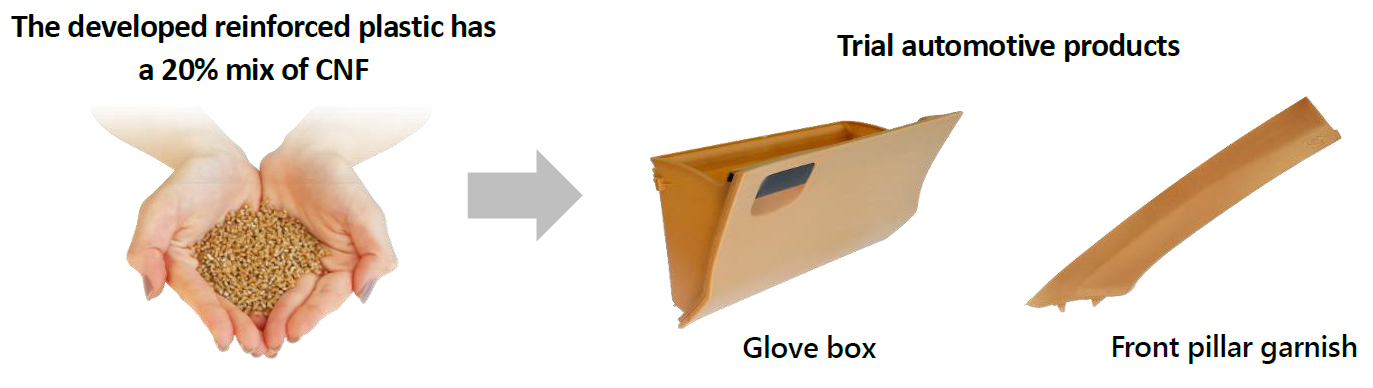

The newly developed CNF-reinforced plastic combines 20% CNF in a general purpose polypropylene for automotive interior and exterior components.

In practical applications, reduced impact resistance from the inclusion of CNF was initially an issue which the company overcame with its material mix design and kneading expertise to raise impact resistance to a level suitable. The company will continue to lower costs in cooperation with CNF material manufacturers.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more