Oeko-Tex 100 for Technical Absorbents

Latest range has been engineered to provide enhanced softness and conformability while improving drying times.

26th January 2026

Innovation in Textiles

|

Grimsby, United Kingdom

Reusable hygiene products such as baby nappies and continence products are now a growing market as an increasingly viable alternative to single-use disposables.

Technical Absorbents, based in Grimsby, UK, is playing an active role in their development with many companies following the development of its washable superabsorbent fibre (SAF)-containing fabrics.

The company’s SAF is based on acrylic acid and manufactured from a proprietary blend of polymers in an environmentally-friendly water based process to create an aqueous solution. This solution is then extruded in a hot air stream to dry and cure it in filament form before being crosslinked in order to control the required degree of absorbency.

SAFs performance in terms of absorbency is unrivalled, capable of absorbing 200 grams of water per gram of fibre, although such high absorbency is seldom called for and there is a trade off between the level of absorbency and gel integrity.

It’s also incredibly fast to absorb compared to SAP powders due to its high surface area and cylindrical shape. It forms a magnetic bond with the water it’s absorbing that is difficult to break, making it ideal for absorbent hygiene products (AHPs) such as diapers.

SAF is also truly integrated into the nonwoven constructions with no danger of shedding, whereas constructions containing SAP in powder form usually need heat sealing. Its polyacrylate structure also makes it safe to use, and it is FDA approved for food applications.

“Normally, washing them, is the last thing you’d want to do with such nonwovens because in regular structures the SAF becomes gel like and the product will fall apart,” explained Technical Absorbents product development director John Rose. “Nevertheless, our R&D team has succeeded in achieving this specifically for the reusable hygiene market.

“After feedback from manufacturers, our latest range has been tested in-house to withstand up to more than 250 washes at 60°C. At this point, they still retain 90% of their original absorbency. They have also been validated for up to 100 washes at an external test house.”

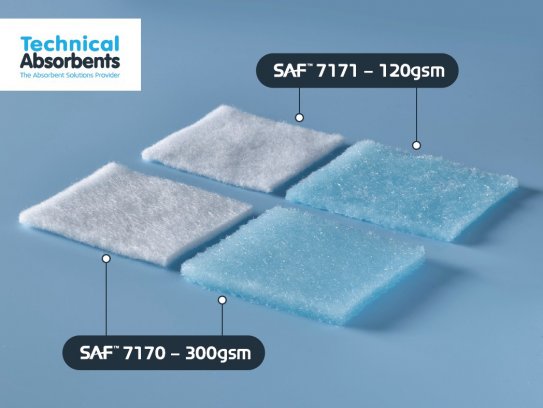

The latest washable SAF fabric range, which has been engineered to provide enhanced softness and conformability while improving drying times consists of three specific grades –7144, which is aimed at period/light incontinence hybrid products and provides a great starting point for companies looking to enter the market with a high performing absorbent core, 7171, a 120gsm fabric suitable for period products and 7170, which at a weight of 300gsm, has been designed with heavier incontinence and bed mat developments in mind.

“We can work with customers to adapt the fabrics as required and look at adding additional laminate layers if needed,” Hope added.

In addition to hygiene products and food pads, other major end-use markets for regular SAF include wound healing, with SAF dressings meeting the need for high absorbency for exudated would healing, providing a controlled environment without wearing. These dressings can be worn for an extended period of time which cuts down the number of changes required.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more