APJeT presents planet-friendly finishing process

Process creates stable bonds between gold electrodes that are printed into ultra-thin polymer sheets.

10th January 2022

Innovation in Textiles

|

Japan

A method of impriving the flexibility of ultra-thin electronics, such as those used in bendable devices or clothing, has been developed at the Riken Centre for Emergent Matter Science (CEMS) and the Riken Cluster for Pioneering Research (CPR) in Japan.

It involved the use of water vapor plasma to directly bond gold electrodes fixed onto separate ultra-thin polymer films, without needing adhesives or high temperatures.

As electronic devices get smaller and smaller, and the desire to have bendable, wearable and on-skin electronics is increasing, conventional methods of constructing these devices have become impractical, the Japanese developers say in Science Advances.

One of the biggest problems is how to connect and integrate multiple devices or pieces of a device that each reside on separate ultra-thin polymer films. Conventional methods that use layers of adhesive to stick electrodes together reduce flexibility and require temperature and pressure that are damaging to super-thin electronics. Conventional methods of direct metal-to-metal bonding are available, but require perfectly smooth and clean surfaces that are not typical in these types of electronics.

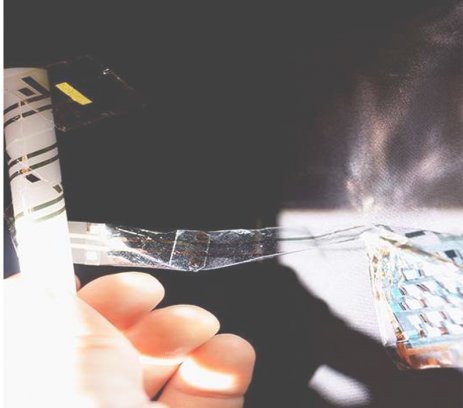

The water-vapor plasma-assisted bonding technique developed by the researchers, led by Takao Someya at Riken CEMS/CPR, avoids these issues. The process takes less than a minute at room temperature, followed by a 12-hour wait. The process creates stable bonds between gold electrodes that are printed into ultra-thin – two thousandths of a millimetre – polymer sheets using a thermal evaporator.

“This is the first demonstration of ultra-thin, flexible gold electronics fabricated without any adhesive,” says Kenjiro Fukuda, senior research scientist at Riken CEMS/CPR. “Using this new direct bond technology, we were able to fabricate an integrated system of flexible organic solar cells and organic LEDs.”

Experiments showed that water-vapor plasma-assisted bonding performed better that conventional adhesive or direct bonding techniques. In particular, the strength and consistency of the bonds was greater than standard surface-assisted direct bonding. At the same time, the material conformed better to curved surfaces and was more durable than what could be achieved using a standard adhesive technique.

As proof of concept, the team integrated ultra-thin organic photovoltaic and LED-light modules that were printed on separate films and connected by five additional polymer films. The devices withstood extensive testing, including being wrapped around a stick and being crumpled and twisted to extremes. Additionally, the power efficiency of the LEDs did not suffer from the treatment. The technique was also able to join pre-packaged LED chips to a flexible surface.

“We expect this new method to become a flexible wiring and mounting technology for next-generation wearable electronics that can be attached to the clothes and skin,” says Fukuda. “The next step is to develop this technology for use with cheaper metals, such as copper or aluminium.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more