Lenzing completes expansion at Austrian site

Applications include plant propagation systems and dessicant bags.

20th October 2025

Innovation in Textiles

|

Weinheim, Germany

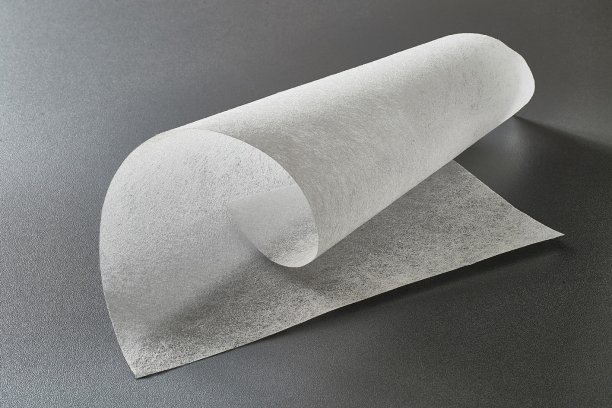

Freudenberg Performance Materials has developed new chemical binder-free PLA/wood pulp nonwovens addressing the needs of specific segments including plant propagation systems, packaging, filtration, apparel and healthcare.

This unique combination is achieved via the wetlaid process. Conventional PLA nonwovens, which are made using spunlaid technology, can only accommodate polymeric raw materials.

Wetlaid nonwovens can be manufactured with a mix of polymeric and non-polymeric materials and the water absorption and biodegradability of wood pulp have been combined the high strength and hot sealability of PLA. As such, the product is 100% bio-based, as well as being binder-free.

In horticulture, PLA/wood pulp wetlaid materials achieve the ideal balance between good water absorption, rooting and degradation properties due to the wood pulp and the high strength provided by the PLA. These properties are required in plant propagation systems such as vegetable growing, flower cultivation and forestry. The new PLA-based products complement the current range of plant propagation wetlaid materials offered by Freudenberg based on different component mixes including wood pulp, polypropylene, polyester and viscose.

For packaging, PLA/wood pulp wetlaids open up new sustainable opportunities by replacing plastic-based packaging in applications such as desiccant bags while other applications include embroidery backings and interlinings for apparel, and wound dressings for the healthcare market.

The two-component mix is flexible, allowing for a wide range of product variants.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more