New airbag structure from Toyoda Gosei

Opinion

The emergence of new digital tools for the apparel and footwear industry provides designers and brands with exciting sustainable innovation opportunities.

28th February 2018

Anne Prahl

|

UK

The emergence of new digital tools and technologies for the apparel and footwear industry provides designers, brands, manufacturers and retailers with exciting sustainable innovation opportunities, which cover the entire product lifecycle from design and development, manufacturing, sales and consumer use to the product’s end-of-life.

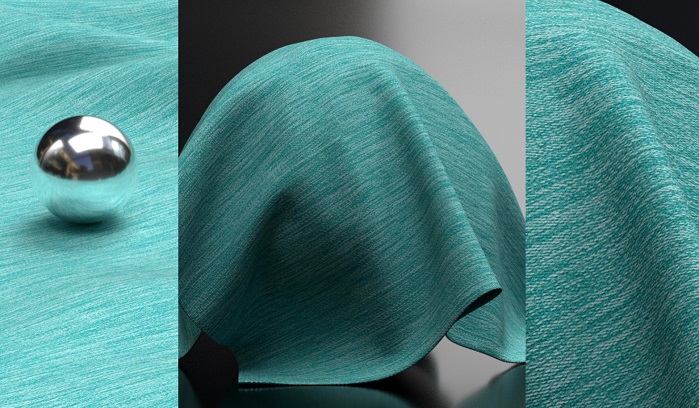

3D design software is an efficient tool to make earlier and better-informed design decisions, which are likely to reduce the need for sampling and prototyping and allow designers to spend more quality time to be creative. An important element of 3D design visualisation is the emergence of material digitalisation tools, which have the potential to reduce the need for physical material swatches and therefore decrease the vast amount of sample yardage created by fabric suppliers each season, as well as cut down on the number of physical product prototypes, as some material decisions can be made virtually.

A great example is Allegorithmic’s Substance software, which consists of 3D painting tools and textures, as well as the ability to render and export files for use in design programs. The company have recently launched a new digital collection of technical sportswear fabrics in collaboration with textile manufacturer TexRay, which are available to use as they are, or can be manipulated by the user to experiment with different colours or other attributes. As previously reported in ‘3D digital technologies: Material focus’, digital material libraries such as swatchbook.us and The Material Exchange, are also excellent tools to reduce the wasteful production of physical material samples, as earlier and collaborative material decisions can cut down on physical product samples.

For many companies starting out on their digital journey, the costs of 3D software packages and need for up-skilling are prohibitive and therefore services such as virtuality.fashion can be effective. The company offer a service, which transforms 2D sketches into 3D virtual prototypes; these can then be used to discuss and finalise designs, materials, fits and colourways before any physical sampling takes place.

Utilising digital manufacturing technologies, such as 3D knitting, can provide significant sustainability benefits. These include the reduction of transportation impact - as machines can be installed locally, material waste reduction - as only the material needed for the product will be produced and the elimination of excess stock through on-demand manufacture. An added bonus is the creation of personalised or customised products, leading to greater product longevity, as the consumer is likely to wear these products for a longer period of time.

An example of this approach is Ministry of Supply’s ‘3D Print-Knit’ blazer, which reduces waste by over 30 per cent compared to traditional cut and sew methods. In addition, the team invite customers to visit their store to create a custom order, where they can choose body colours, cuff and button details to provide a personalised design.

This example also ties in with the concept of experiential retail, where brands and retailers create engaging shopping and brand experiences for the consumer. One important aspect is the ‘virtual try-on’, which is emerging for both apparel and footwear. Nike’s ‘Makers' Experience’ merges digital design with traditional shoe making, allowing consumers to try on shoes before they are custom-made on the spot in less than 90 minutes. Virtual try-on is an effective strategy to enhance consumer loyalty, as well as allowing the customer to make better buying decisions to choose products, which fit better and will become long-term favourites. Virtual try-ons are also relevant for on-line shopping, as this service can help on-line shoppers to create their personal avatar, in order to find the perfect fit and style. This approach can reduce returns and unworn clothing piling up in shoppers homes or being discarded prematurely.

Employing digital technologies including blockchain and QR codes can also enable more sustainable use, as companies can provide the consumer with information on how to care for a new purchase in order to extend wear or inform them where the product can be taken for reuse, should they no longer want to wear it. At the product’s end-of-life, digital tracking and sorting technologies can also facilitate efficient recycling.

Berlin based sustainable platform circular.fashion offers a service whereby a circularfashion.ID is created for a product, which acts as an interface for brands, customers and textile collectors as well as textile recycling companies. Brands can utilise the laser-engraved or woven QR code to provide the customer with manufacturing transparency, as well as gain insights into the use of their products, while textile collectors and sorters receive valuable information to decide whether to reuse or recycle a product and recyclers can find out about all the components and fabric composition to enable efficient textile-to-textile recycling.

The recent PI Apparel conference in Los Angeles featured disruptive technologies for digital product creation and data management and for the first time, paid special attention to the question of how the apparel and footwear industry can leverage technology to enable strategic sustainable innovation.

Choosing from keynotes, panel discussions, focus groups and one-to-one networking sessions, delegates were able to explore a range of subjects including lessons learnt from pioneers and early adopters in the field of sustainable innovation, alternative approaches to material innovation and manufacturing, as well as utilising data and digital tools to engage the consumer.

During a panel discussion on the convergence of sustainability, innovation and technology, Arthur Kononuk, Creative Director and Co-Founder of tentree shared how the brand utilises digital technology to contribute to positive environmental impact. All products are made from sustainable and responsibly sourced materials including organic cotton, recycled polyester, cork and coconut and for every item purchased, the company plant ten trees in over ten countries, with a goal to plant 1 billion trees by 2030. Each item of clothing comes with a unique tree code, which allows customers to track their trees via the brand’s website to see where they have been planted and what impact they have on the local environment and community.

Focusing on engaging the consumer in product creation, London based software solutions experts Unmade showcased their take on the sustainability implications of on-demand manufacturing. The company provide fashion brands with the digital tools and support systems to create customisation experiences for their customers, while manufacturing bespoke products at an industrial scale. This approach, where product is shown to the consumer before it is made, has the added benefit of producing only what the consumer wants, therefore cutting down on excess stock and waste at the end of the season.

Automation is another hot topic and we have already seen commercial adoption in the footwear industry with adidas Speedfactory, an automated local production unit in Germany. Automated manufacture is also gathering momentum for apparel, promising compelling sustainability benefits such as reducing transportation impact through local manufacture and the elimination of excess stock through on-demand manufacture.

Atlanta based SoftWear Automation presented their fully automated Sewbot systems for home goods, footwear and apparel, highlighting opportunities for the viability of made-to-measure high volume basic garments such as t-shirts and the benefits of cost-effective local manufacture, which further results in job creation for skilled engineers and technicians to support the fully automated manufacturing process. However, the adoption of automated sewing machines is predicted to have significant social and ethical impacts, as the need for human workers in traditional manufacturing regions will be drastically reduced. Therefore, the fashion industry must begin to plan for up-skilling or retraining workforces affected by this significant change and embrace the opportunity to provide workers with higher-value and more fulfilling jobs in the future.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more