Veocel lays foundation for sustainable nonwovens future

Lenzing Group has announced the introduction of Eco Cycle technology under its specialty nonwoven brand Veocel.

1st January 1970

Innovation in Textiles

|

Miami, FL/Lenzing

The Eco Cycle technology involves the upcycling of a substantial proportion of pre-consumer cotton scraps. © Lenzing

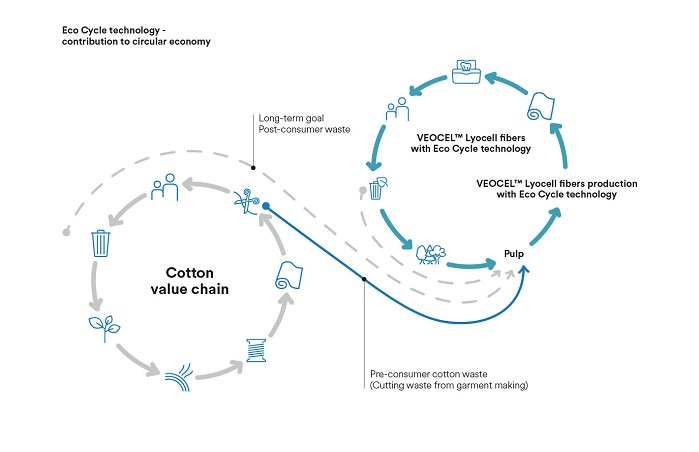

Lenzing Group has announced the introduction of Eco Cycle technology under its specialty nonwoven brand Veocel. Eco Cycle technology is a testament to the Veocel brand’s commitment to driving sustainability and circularity in the nonwovens industry. The technology involves the upcycling of a substantial proportion of pre-consumer cotton scraps, for example, from garment production, and mixing with sustainably sourced wood pulp, to produce pure new virgin Veocel branded lyocell fibres for nonwoven applications.

“Since the inception of the Veocel brand, we have been pioneering the development and application of sustainable nonwoven technologies and applications,” said Jürgen Eizinger, Vice President of Global Business Management Nonwovens, Lenzing.

“Eco Cycle technology encompasses our commitment to providing the industry with sustainable raw materials and driving circularity in the nonwoven industry ecosystem. Promoting circular economy will be a key strategy of the Lenzing Group in the long run. Eco Cycle technology will enable us to a bold new step in driving the discussion of circularity of natural botanic materials in the ecosystem.”

Eco Cycle technology leverages Lenzing’s closed-loop production process. © Lenzing

Eco Cycle technology leverages Lenzing’s award-winning closed-loop production process to produce virgin Veocel branded lyocell fibres with upcycled pre-consumer cotton scraps and wood pulp from sustainable sources. The process recovers more than 99% of the solvent and water in a closed loop and repeatedly feeds it back into the production process. This results in low levels of emissions and absence of optical brighteners in the Veocel branded lyocell fibre production, the company explains.

“Produced using an environmentally friendly and sustainable process, Veocel Lyocell fibres are certified clean and safe,” added Mr Eizinger. “With Eco Cycle technology, these fibres for nonwoven applications offer nonwoven roll-good manufacturers a convenient way to contribute to the circular economy without the necessity to engage in mechanical recycling which possibly produce harmful by-products and emissions. This holistic approach enables us to set new benchmarks in circularity.”

Produced using an environmentally friendly process, Veocel fibres are certified clean and safe. © Lenzing

Veocel branded lyocell fibres have been certified Biobased by the United States Department of Agriculture (USDA). Blending Veocel branded Lyocell fibres with other fibres is said to add a greater degree of smoothness and absorbency to nonwoven fabrics and improve the liquid absorbency in wet wipes, offering a more convenient way to clean surfaces.

Further reading

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more