Circulose teams up with Tangshan Sanyou

Chinese producer commits to purchasing regenerated pulp over a five year period.

24th July 2025

Innovation in Textiles

|

Danville, VA, USA

Polycotton recycling pioneer Circ has signed a new agreement with Sanyou Chemical Fiber of China’s Tangshan Sanyou Group, aimed at further accelerating the scaling of recycled lyocell fibres.

Sanyou has committed to purchase pulp for a period of five years from Circ’s first commercial-scale facility, which is expected to be operational in 2028.

The collaboration between Sanyou and Circ will result in the production of lyocell staple fibres with 30% recycled content.

“As one of the leading global cellulose producers, Sanyou’s commitment to Circ demonstrates the quality of our product,” said Peter Majeranowski, CEO of Circ. “Core to Circ—from our technology and products to our partnerships and business strategies—is creating forward momentum towards a truly circular economy in the global fashion industry, and strategic partnerships such as with Sanyou are crucial for the realization of this goal.”

Sanyou’s commitment will ensure that its customers have access to high-quality recycled Circ lyocell at a time when demand for sustainable options is outpacing production and brands are looking to diversify their production markets.

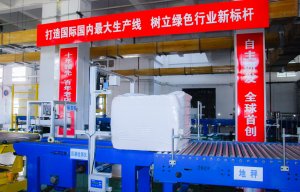

Last month, Tangshan Sanyou opened a new test facility aimed at advancing circular textile innovation in man-made cellulosic fibre (MMCF) production at its plant in Tangshan, China.

The ten-ton pilot line will trial a new solvent-based process that directly converts waste cotton textiles into high-quality viscose fibres for use in the company’s ReVisco recycled MMCFs.

This development builds on several years of steady investment by the company in integrating NextGen fibre solutions across its MMCF offerings. Since 2018, Tangshan Sanyou has worked with a range of recycled textile feedstocks to support the commercial transition toward more circular and lower-impact fibre production.

Tangshan Sanyou has already achieved market readiness to scale ReVisco production to 200,000 tons per year, based on market demand.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more