Circulose teams up with Tangshan Sanyou

Market readiness to scale ReVisco production to 200,000 tons per year.

4th June 2025

Innovation in Textiles

|

Tangshan, China

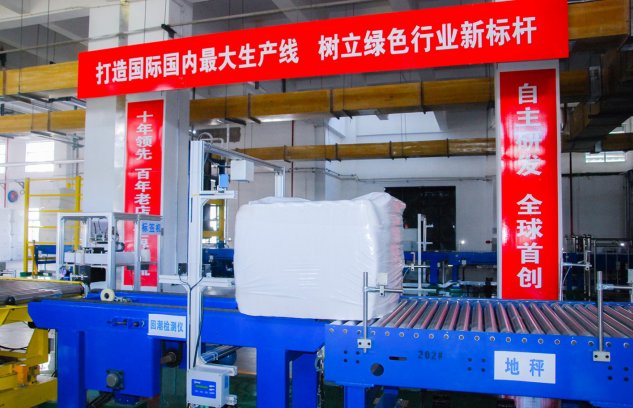

Tangshan Sanyou has opened a new test facility aimed at advancing circular textile innovation in man-made cellulosic fibre (MMCF) production at its plant in Tangshan, China.

The ten-ton pilot line will trial a new solvent-based process that directly converts waste cotton textiles into high-quality viscose fibres for use in the company’s ReVisco recycled MMCFs.

This development builds on several years of steady investment by the company in integrating NextGen fibre solutions across its MMCF offerings. Since 2018, Tangshan Sanyou has worked with a range of recycled textile feedstocks to support the commercial transition toward more circular and lower-impact fibre production.

Key milestones have included becoming the first conventional MMCF producer to integrate Circulose recycled cotton pulp into its ReVisco viscose staple fibre line at a 30% blend, including the development of black viscose and trials for additional colourways.

Tangshan Sanyou recently renewed its partnership with the new ownership of Circulose as it moves towards reopening its mill in Sweden.

Södra’s OnceMore recycled cotton pulp has also been integrated into ReVisco modal and viscose fibres in a 20% blend and the company is successfully producing viscose fibre using hemp and Juncao as well as lyocell derived from recycled textile inputs as other alternative feedstocks.

Tangshan Sanyou has now achieved market readiness to scale ReVisco production to 200,000 tons per year, based on market demand.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more