Lightweight Toray solutions at JEC

Stronger recycled fibres minimise breakages and low resin residue assists in better post-processing.

4th November 2025

Innovation in Textiles

|

Tokyo, Japan

Tokyo-headquartered Toray Industries has developed an improved technique for recovering valuable carbon fibres from thermoset resins in composites – a notable industry challenge.

Pyrolysis with a reducing agent is gaining traction to recover the fibres from thermoset composites, notably for injection moulding applications. To broaden applications, however, there is a need for technologies that can suppress thermal damage to the fibres and control resin residue – and which can accommodate diverse types of composite waste.

Organic synthesis

Toray has applied its accumulated expertise in organic synthesis and polymerization to develop a decomposition agent that breaks down degradation-resistant, three-dimensionally crosslinked thermosetting resins at lower temperatures than conventional methods.

The company has used this agent to decompose composite waste from aircraft, wind turbines, automobiles and other sources. The recycled carbon fibre from the process retains over 95% of the single-fibre tensile strength of virgin carbon fibre and Toray also expects carbon dioxide emissions generation from this technology, once commercialised, to be 50% of that for manufacturing virgin carbon fibres.

The resulting stronger recycled fibres minimise breakage in post-processing and the low resin residue and excellent surface quality enable processing for more diverse applications.

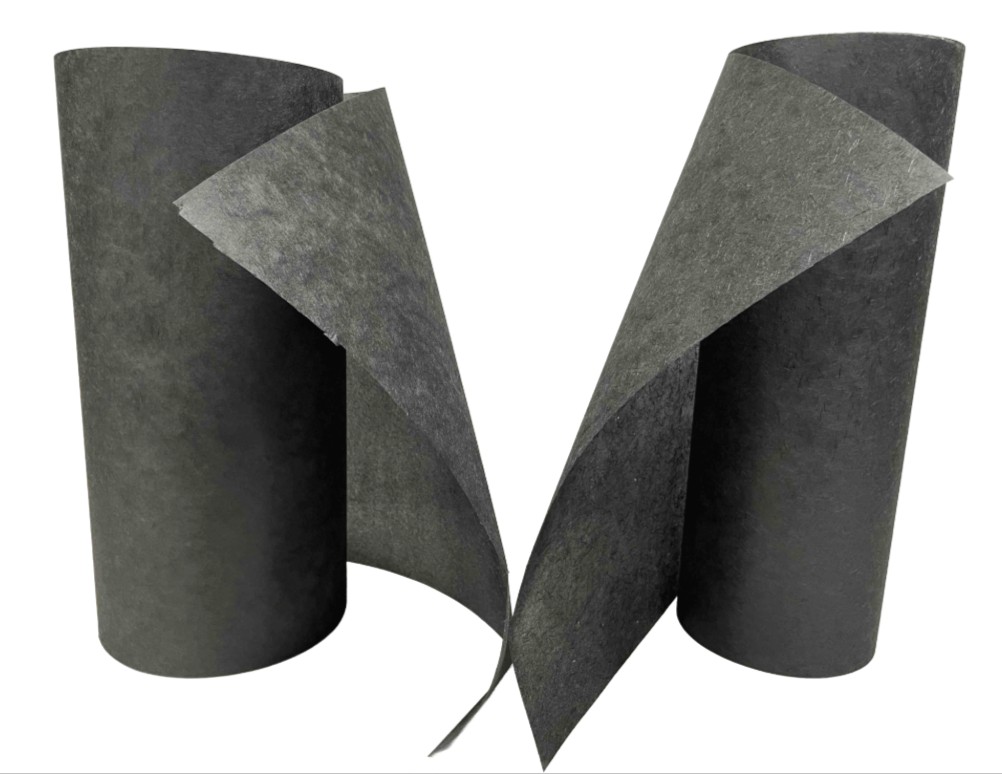

In particular, efforts to disperse short fibres and process them into sheet-form nonwoven fabrics have led to success. The recycled carbon fibres produced using this technology exhibit controllable water dispersibility, allowing for the fabrication of uniform nonwoven structures with a distinctive texture reminiscent of washi – traditional Japanese paper. This fabric combines the functionality of carbon fibre, including radio frequency shielding and thermal conductivity, with the aesthetic appeal of washi. Toray aims to expand applications for this new material across many industries.

The fabric already features in interior and exterior components of a Vision X concept car that Mazda is exhibiting at the Japan Mobility Show at Tokyo Big Sight until November 9th.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more