ReHubs seeks €6-7 billion for bold plan

European action on transitioning to a new sustainable business model for textiles underway.

6th March 2023

Innovation in Textiles

|

Brussels, Belgium

On February 21st, 43 partners of the RegioGreenTex project met in Brussels to kick start a three-year project that aims to change the way textile recycling is managed.

The project intends to map and reduce the difficulties which currently exist in the implementation of a circular economy model within the textile ecosystem across the EU.

Significantly, RegioGreenTex will support tangible solutions at SME level, where textile waste has value. The project will contribute to maintain and develop jobs in the EU textile sector, reshoring the production in Europe and making the EU textile value chain more competitive and resilient. It will also contribute to the EU Green Deal objectives of reducing carbon footprint, energy and water consumption.

Led by Euratex, the project brings together partners from 11 European regions, with 24 SMEs pioneering solutions to recycle textile waste. Together the SMEs cover various value chain segments for circular textiles – sorting, recycling from material to fibre, the removal of contaminants and the processing of recycled fibres into new textile materials. The project will also promote the development of five ReHubs in some of the most important textile regions in the EU.

RegioGreenTex is supported by the European Commission through the Interregional Innovation Investments Instrument (I3) and will be coordinated by the European Innovation Council and SMEs Executive Agency (EISMEA).

As part of the European Regional and Development Fund (ERDF), the I3 instrument aims at supporting interregional innovation projects in their commercialisation and scale-up phases, giving them the tools to bring their project to investment level. This instrument focuses on strengthening economic cohesion in the EU by helping businesses work with companies in other regions.

“RegioGreenTex will support our companies in making the transition towards a new sustainable business model,” said Dirk Vantyghem, director general of Euratex. “We’re happy to have 24 SMEs involved, who will directly benefit from the action. The project should also mobilise regional authorities to engage in textile waste recycling, which can give a new dynamic to the textile industry at large.”

Sorting 4.0

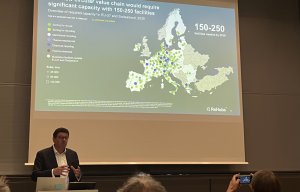

The first project to come out of the ambitious EU-wide €6-7 nillion ReHubs initiative meanwhile aims to have a fully operational new Industry 4.0 automated textile waste sorting plant operational in Switzerland by the end of 2024, with an annual capacity of 50,000 tons.

Textile waste sorting has been identified as a major bottleneck in European plans for fibre-to-fibre regeneration, and there is a need to ensure that high quality raw materials can be made available on a large scale.

The Transform Textile Waste into Feedstock project has been initiated by Texaid, with well-known stakeholders in the textile value chain, including Concordia, CuRe Technology, Decathlon, Inditex, Indorama Ventures, L’Atelier des Matières, Lenzing, Marchi & Fildi, PurFi and Södra.

“This project will enable Industry 4.0 scalable sorting,” says Martin Böschen, Texaid CEO. “In order to reach that target we are starting with a technology assessment to jointly evaluate technologies and the business case for scaled sorting for reuse and recycling, followed by establishing a demonstration plant and going to full scale by the end of next year.”

Texaid, headquartered in Steinhausen, Switzerland, is a circular service specialist in the professional collection, sorting, repair, reselling and recycling of textiles and footwear and processes more than 280 million items or 80,000 tons annually.

With operations in Europe and North America and more than 1,000 employees, the company is contributing daily to saving millions of textiles from landfill or incineration.

Also involved in the project is Worn Again Technologies which since 2012 has been involved in the development of a unique polymer recycling technology which separates, decontaminates and extracts polyester and cotton/cellulose from non-reusable textiles. The dual PET and cellulose outputs can be reintroduced into supply chains to become new fibre, textiles and products as part of a continuous cycle.

The regenerative recycling technology is being brought to life by an expert team and strategic partners. Worn Again Technologies has strategic investors including Sulzer Chemtech, the global market leader in mass transfer, static mixing and polymer solutions for petrochemicals, refining and LNG, Oerlikon, Mexico-based Himes Corporation, a garment manufacturer and textiles producer Directex, as well as the support of influential brands and partners such as Kering, ASICS Europe, Sympatex, Dibella and Dhana.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more