Reading the waves with SonoTextiles

Tiny microphones are being knitted into the fabric covering army helmets to reduce the risk of soldiers developing hearing injuries.

26th September 2017

Innovation in Textiles

|

Nottingham

Tiny microphones almost invisible to the naked eye are being knitted into the fabric covering army helmets to reduce the risk of soldiers developing hearing injuries, thanks to new research by Nottingham Trent University.

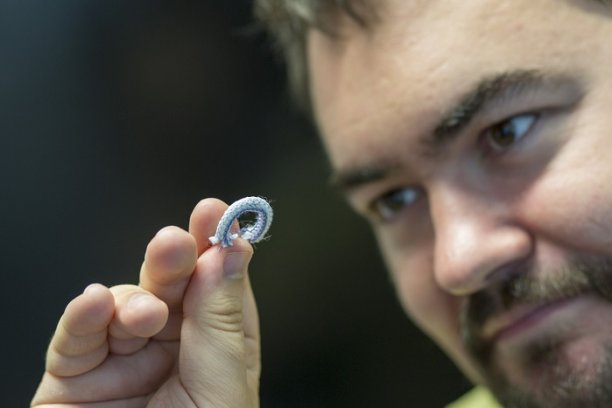

A project led by the Advanced Textiles Research Group (ATRG) of the School of Art & Design will develop technology to measure and record the levels of noise which soldiers experience in the field to prevent hearing damage. Professor Tilak Dias and research fellow Dr Theodore Hughes-Riley are using microelectromechanical system microphones (MEMS) which measure the level of noise someone is exposed to over a length of time.

The microphones – when knitted into the fabric covering regular personnel headwear – will be undetectable to the user and avoid interfering with military activities. “This innovation will dramatically reduce the risk of service personnel injured due to long-term noise exposure,” said Professor Dias. “By integrating a low-cost and discrete dosemeter directly into a textile, such as a helmet cover, the noise exposure of personnel will be monitored and stored, providing the data necessary to take preventative action in the future.”

Professor Dias and Dr Hughes-Riley have received a grant from The Defence & Security Accelerator – Open Call for Innovation to develop a prototype helmet with two microphones, one above each ear.

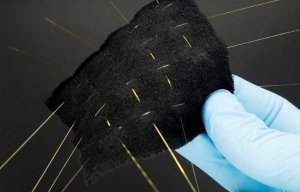

A short exposure to sound levels exceeding 140 decibels can cause permanent hearing damage, with a single gunshot capable of producing a sound level of 140 to 170 decibels. The microphones will be embedded in yarns using ATRG’s e-yarn technology platform to keep them dry and allow the helmet covers to be washed. The positioning of the microphones above each ear is vital as an acoustic injury is more likely to be asymmetric due to some military activities, meaning one ear might be affected more than the other.

In addition to preventing injury, the helmet will make it simpler for the military to continue to fully comply with the Control of Noise at Work Regulations which limit the level of noise that an employee can be exposed to in the workplace over a period of time.

“Research has shown that the effect of hearing loss on an individual’s speech comprehension can severely affect their ability to communicate with others, and affect their quality of life,” said Dr Hughes-Riley. “So it’s important that soldiers are given the best protection possible to prevent them from experiencing noise levels which can cause injury.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more