GKD expands portfolio into spiral fabric belts

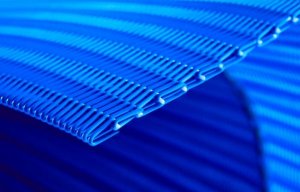

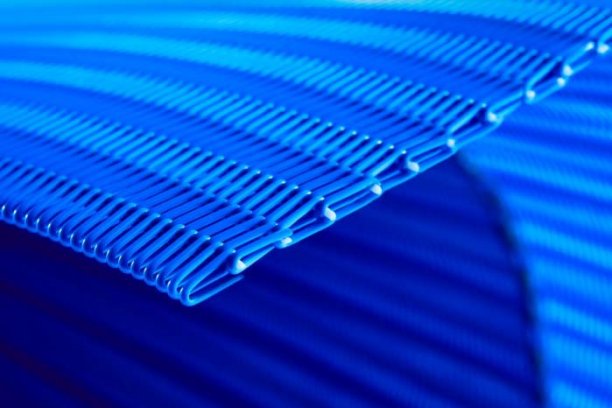

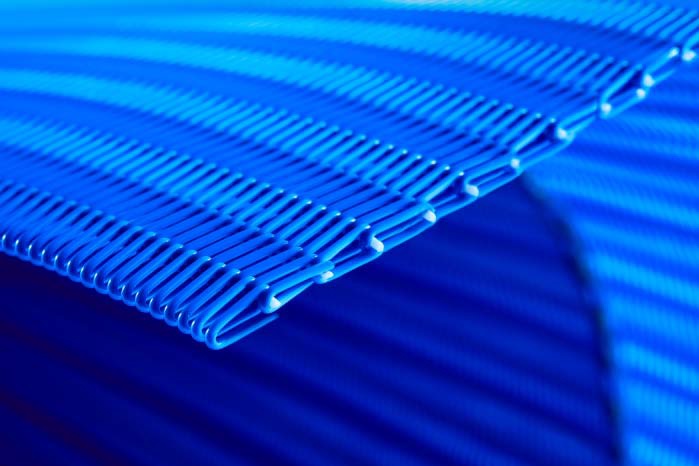

The Conductive 7690 forming belt and coated glass hybrid fabric for use in single-belt and double-belt dryers were at the heart of the display.

3rd May 2017

Innovation in Textiles

|

Heslington

GKD – GEBR. KUFFERATH AG, a leading market leader for metal and plastic woven solutions, has recorded a particular interest from visitors in the company’s newly developed woven belts for forming, binding and drying nonwovens at the INDEX trade fair that took place in Geneva, last month.

The Conductive 7690 forming belt, as well as coated glass hybrid fabric for use in single-belt and double-belt dryers were at the heart of the display, according to the manufacturer. “Since these products have already proven themselves in real-world applications at well-known reference customers, numerous trade fair visitors took the opportunity to engage in detailed discussions,” the company reports.

“The feedback we received from visitors to our stand was much stronger than at the INDEX event three years ago, both quantitatively and qualitatively.”

Many of the visitors arrived at the GKD stand with questions about the innovative Conductive 7690 forming belt. Its rough structure is said to allow this belt type to reach production speed in a very short time without the need for prior, time-consuming roughening. Alongside this high traction, homogeneous web formation and optimum nonwoven removal serve to support process efficiency, the manufacturer explains.

According to the company, visitors were particularly interested in the cleaning performance of the Conductive 7690, which had received praise from the customers. Thanks to the new belt design, soiling can be removed more easily and quickly than with conventional belts. With its special monofilaments, the belt is also said to reliably discharge process-based electrostatic charges.

The coated glass hybrid fabric for use in single-belt and double-belt dryers, first presented by GKD in Geneva, also attracted many specific questions. Glass strands woven into the material in the warp direction lend this fabric lightness, while also ensuring a high degree of lateral stability. A high-grade PFA coating is designed to ensure that even products that are difficult to remove will not stick.

“This low soiling tendency contributes to significantly longer cleaning cycles and thereby also to greater productivity,” the company reports. Depending on the intended application, GKD designs this belt type as magnetic or non-magnetic.

Two belt types for high-speed processes in the rapidly growing market of hygiene nonwovens rounded off the full range of belts on show. Thanks to their specific construction from metal with special plastic cords integrated in the direction of rotation, the self-regulating V-crimp-type belts from GKD are said to be highly flexible.

“This also qualifies them for very tight bending radii and high forces for uninterrupted production. With their reliable discharge of electrostatic charges, belts in the Conducto range also facilitate safe and efficient processes,” the company explains.

In the field of polymer filtration, metallic mesh filter media meet the strictest standards for central filters, spinning beams and blower filters, according to the manufacturer. Multi-ply structures produced from optimised plain Dutch weave for process-specific filter discs or cartridges are said to guarantee reliable particle retention and a long service life of the screen changers.

In the spinning beam, tailor-made fabric plies optimise filtration of the fusion flow. Blower screens made of large-format honeycomb supporting plates, which employ a specially pre-treated mesh design on both sides, aim to improve fibre flow by creating a homogeneous flow.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more